You can’t afford a failure in the field. Lost hours, dollars, and trust wash away every second your system is offline. That’s why OILCO builds in quality at every step of the manufacturing process. We start with superior engineering, use the best machines in the business, and rigorously test.

Offering the widest application range – 1.5” through 24” ID sizing – few industrial applications are out of reach for OILCO swivel joints. We use multiple radial ball bearing tracks, tapered roller bearings, various packing seal arrangements, and offer a combination of construction metals.

OILCO swivel joint product features

O-ring and v-ring design packing chambers

The standard OILCO o-ring is a single-point pressure seal design. Contained within opposing grooves, the compression along the sealing surfaces promotes a positive adherence while maintaining rotation and keeping friction loss to a minimum.

The OILCO v-ring is a triple seal configuration, spring energized and self-adjusting for normal wear. A Teflon® spring adapter and equally spaced compression springs force the three interlocking seals to flare and constantly maintain an optimal positive seal.

Buna-N is standard, but Viton, Teflon®, Kalrez®, Chemrez®, EPDM and EPR are available options in either format, depending on the product and customer requirements.

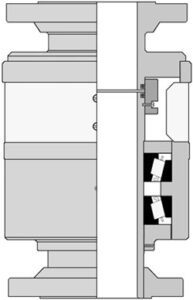

Tapered roller bearing swivel joints

OILCO uses various ball bearing and dimensional engineering to achieve the highest moment load to swivel joint ratio in the industry. The OILCO swivel joint line starts with a graduated ball bearing design in dual track raceways.

For extreme load carrying, OILCO offers a swivel line incorporating the tapered Timken® roller bearing. Virtually friction free movement, the roller bearings bring superior durability and permanent alignment. This setup affords simple seal replacement and easy internal maintenance.

Advanced designs & special applications

Since we’ve been doing this for 85+ years, we’re able to manufacture customized applications in less time than our competitors. Our 90 Series platform is highly adaptable, offering unmatched project flexibility and the performance reliability we’re known for.

Find your fit

Choosing the right swivel for your intended use is critical to your success – and ours. Size, material of construction, connection type, seal-to-product compatibility – it’s all an art and a science. We’re here to help. Reach out to us with any questions, and check the blog for further articles about finding the right fit and performing proper maintenance.

OILCO: Reliability at every turn

Proudly designed and manufactured in the USA since 1935, OILCO Liquid Handling Systems’ reliable products keep industries moving. From our unparalleled swivel joint line to our innovative loading arm assemblies, OILCO products are engineered to do more. Put our experience to work for your business.