The unsung heroes of liquid handling systems worldwide, swivel joints are highly customizable. Understanding the information contained in the model number on your swivel is crucial to the unit’s seamless operation – and key to planning your regular maintenance. Here’s how to break down your number.

Information key to identifying a swivel joint

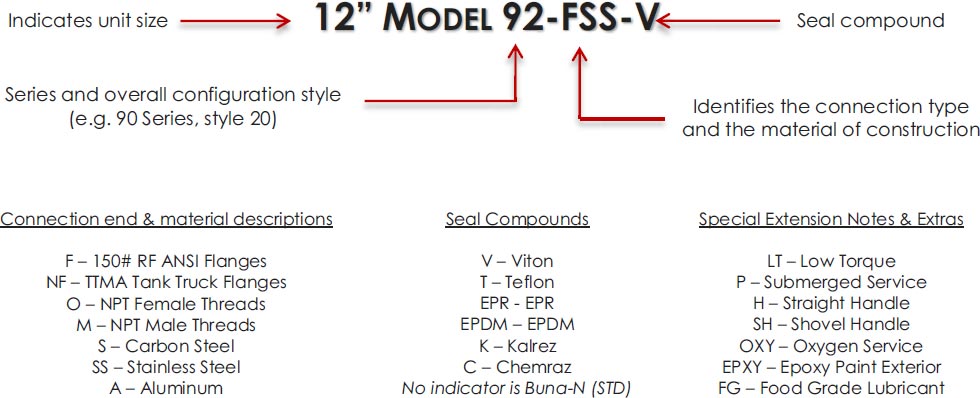

Identifying your swivel model and specifications is easy, once you understand what you’re looking at. For example, if you’re looking at a swivel, it might read this:

12” Model 92-FSS-V

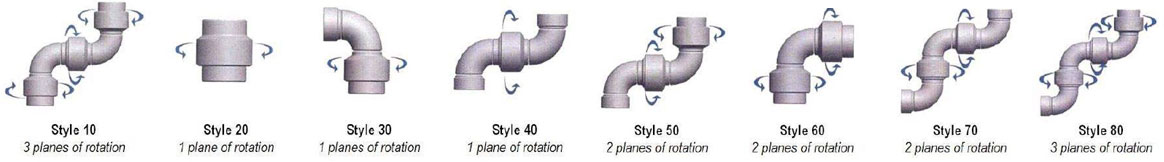

The first number indicates the size of the unit – in this case, it is 12 inches. The next number (92) is a combination of two key elements: Series and configuration. In the above example, the 92 stands for OILCO’s 90 Series swivel product line and indicates the unit is a style 20 meaning it has one plane of rotation.

The first set of letters identifies the swivel’s connection type as well as the material of construction. In this case, FSS stands for 150# RF ANSI Flanges and Stainless Steel.

In this example, the final letter describes the seal compound with V representing Viton.

If your swivel has any special extension notes or additional customizations, they would be indicated by another dash and then more letters (see below).

Alpha coding: Explained

Connection end and material descriptions can include:

- F – 150# RF ANSI Flanges

- NF – TTMA Tank Truck Flanges

- O – NPT Female Threads

- M – NPT Male Threads

- S – Carbon Steel

- SS – Stainless Steel

- A – Aluminum

Seal compounds can include:

- V – Viton

- T – Teflon

- EPR – EPR

- EPDM – EPDM

- K – Kalrez

- C – Chemraz

- No indicator is Buna-N (STD)

Special extension notes and customizations can include:

- LT – Low Torque

- P – Submerged Service

- H – Straight Handle

- SH – Shovel Handle

- OXY – Oxygen Service

- EPXY – Epoxy Paint Exterior

Swivel joint maintenance guidelines

Now that you have your swivel joint identified, be sure to plan for regular maintenance. Our guidelines below can help you maximize your swivel’s operation.

- Only approved OILCO parts should be used for installation and repair.

- Maintenance should never be performed on a unit in service and under pressure.

- Operational pressure should never exceed the working pressure of the swivel joint spool or the affixed end connections.

- Whenever a leak is detected, remove the swivel joint from service immediately and replace the packing with OILCO seal replacement kits. If the unit has experienced wear and is no longer suitable for service, contact the OILCO team.

- Adhere to all factory recommendations and MSDS instructions for proper chemical compatibility and safe fluid handling.

- Safe handling practices should be observed when manipulating swivel joints. Personnel should always wear proper PPE (Personal Protective Equipment).

- Never bolt on, wrap, or weld additional pieces to OILCO swivel joints without first consulting with the factory.

- An approved scheduled preventative maintenance program should include routine examination and care of all swivel joints in and out of service.

- Consult OILCO’s Swivel Joint General Maintenance & Safety Notes for detailed reference to the above care and caution associated with everyday operations.

- Failure to observe all safety warnings can result in property damage or personal injury.

OILCO swivel joints are designed to be included in engineered systems under controlled industrial conditions. All safety procedures, guidelines and policies established by OILCO, the customer, the destination facility, and any supervising government agency must be observed at all times.

Find your fit

Choosing the right swivel for your intended use is critical to your success – and ours. Size, material of construction, connection type, seal-to-product compatibility – it’s all an art and a science. We’re here to help. Reach out to us with any questions, and check the blog for further articles about finding the right fit and performing proper maintenance.

OILCO: Reliability at every turn

Proudly designed and manufactured in the USA since 1935, OILCO Liquid Handling Systems’ reliable products keep industries moving. From our unparalleled swivel joint line to our innovative loading arm assemblies, OILCO products are engineered to do more. Put our experience to work for your business.